Quality carbon insulation for vacuum furnaces

Graphite insulation materials have excellent thermal properties, which can result in improved temperature uniformity and no contamination at elevated temperatures.

Coidan Graphite supply both rigid and flexible insulation options to suit your needs with or without CFC or foil facing.

Rigid insulation

We offer two styles of rigid insulation: Rigitherm CF, which is carbon-bonded carbon fibre, and Rigitherm RF, which is rigidised felt.

Rigitherm CF is easy to machine to complex shapes and tends to have better thermal resistance than the felt, but it’s less able to withstand vibration caused by high gas velocities.

Rigitherm RF is well suited to high pressure quench and more abrasive applications. This is because less dust is present as the boards abrade, and the furnace walls are more durable.

We also manufacture bespoke insulation cylinders, which can be made as either a solid vacuum formed cylinder or as a series of barrel staves bonded together.

For the majority of applications we recommend Rigitherm CF with foil facing on front and back faces. This improves heat uniformity, keeps dust down and prevents excessive oxidation from the rear of the boards.

Flexible insulation

We supply two flexible insulation options: graphite felt and graphite foil. Felt allows the insulation to be shaped around the walls of the furnace, whereas foil acts as a physical barrier between the insulation and the furnace interior.

We can provide flexible insulation in many shapes or sizes to meet your furnace requirements.

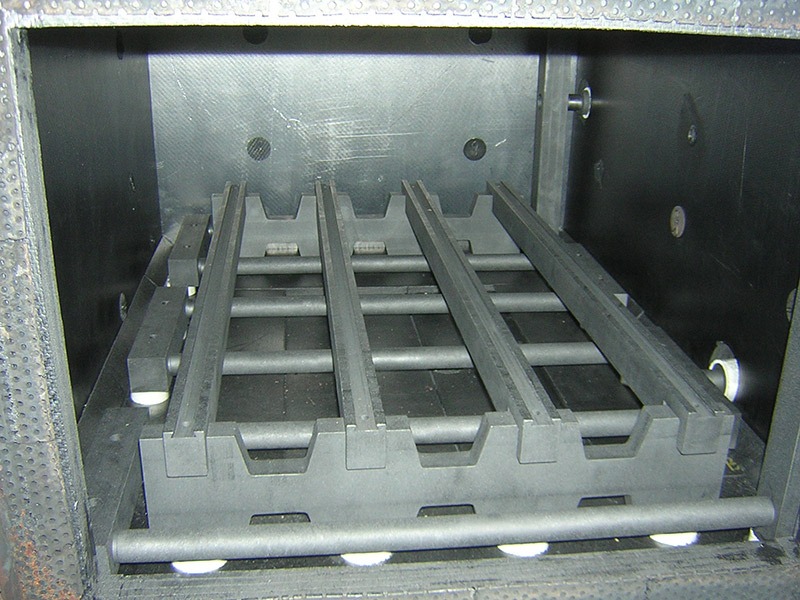

CFC and other hot zone accessories

We offer a diverse selection of materials to help retain the insulation, as well as improving the thermal performance and lifespan of vacuum furnaces.

These include carbon fibre composite (CFC), a lightweight structural element used within a furnace hot zone to protect the insulation and provide strength with a low thermal mass. We can supply a range of CFC products, from angles and channels to furnace bases and protection plates.

If you would like to repair a failing furnace to extend its life to reach your next scheduled maintenance shutdown, we recommend our flexible foil faced CFC liner. This will prolong the life of the furnace, keep all the internal insulation intact and allow the furnace to run until the scheduled repair can be carried out under controlled conditions.

Other accessories include graphite paint and adhesive, as well as molybdenum hangers and carbon braided cord.