Specialist graphite machinists

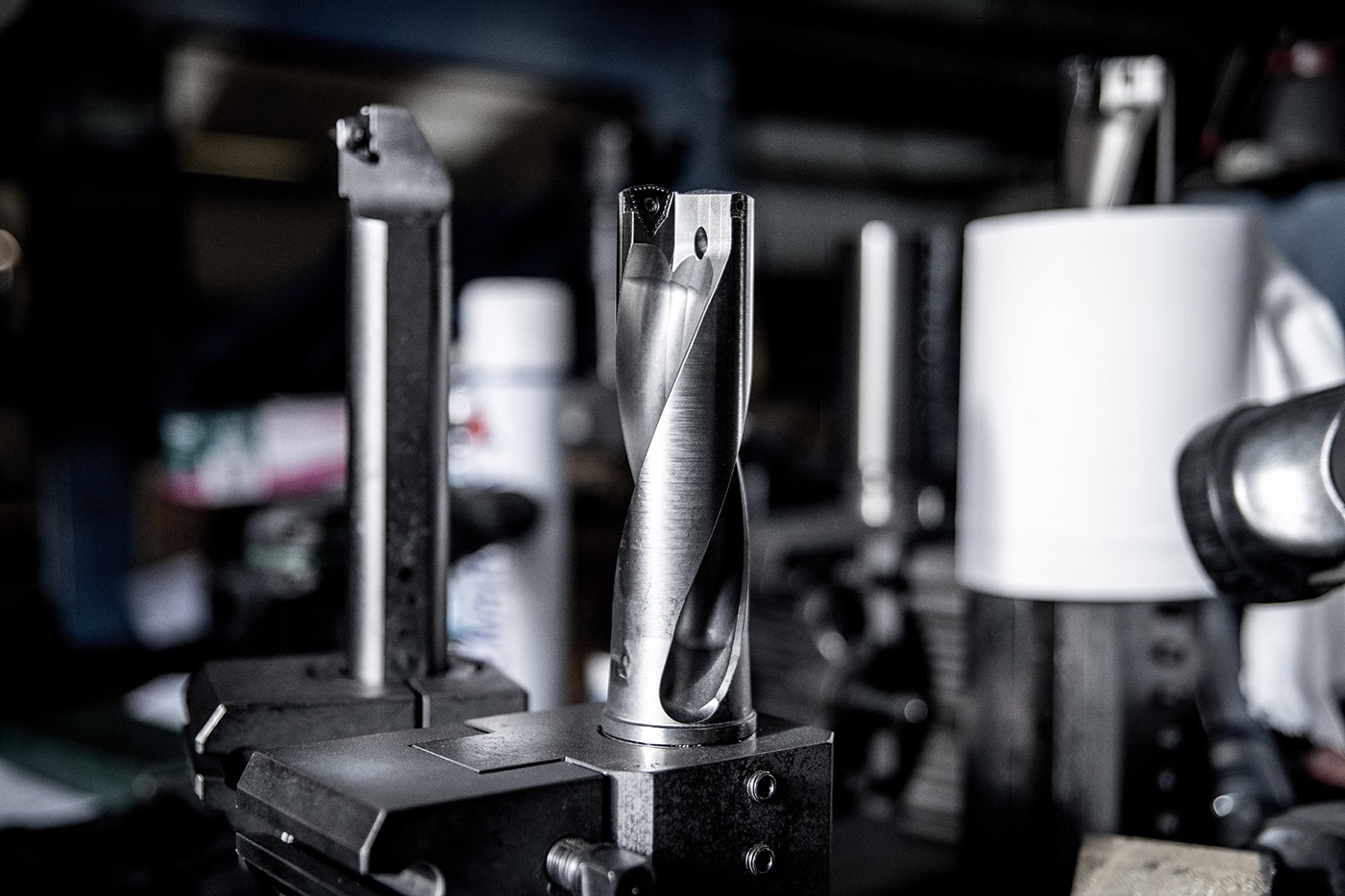

We’ve been precision machining graphite parts since 2004, in addition, many of our staff have been machining graphite since the 1980s, thus we have years of technical expertise on-hand when it comes to these skilled and intricate operations.

Coidan Graphite is one of the UK’s leading suppliers of precision machined carbon and graphite components. Established in 2004, the company has built an excellent reputation for customer service worldwide. Our manufacturing range covers bespoke graphite components for the micro-electronic and semi-conductor industries, to large diameter graphite electrodes and graphite furnace linings over 2000mm diameter.

We supply a full range of materials, which comprise isostatically pressed, extruded, die-moulded, vibration-moulded and expanded carbon and graphite materials, encompassing carbon and graphite insulation and CFC. These materials are matched to the needs of customer applications, we recommend the best material for the application, regardless of the manufacturer, being independent means we are not limited to one manufacturers product range. We have the necessary expertise to undertake the design, manufacture and machining of complex components made from carbon and graphite materials. Our product portfolio is complemented by finishing options such as ceramic coating, graphite resin impregnation and graphite purification.

Certified to ISO 9001:2015, our comprehensive array of CNC machinery allows us to produce accurate parts, with repeatability and consistency ensuring that reliable quality carbon and graphite parts are manufactured.

In addition to large-scale volume production, we can also manufacture one-off, bespoke orders to suit any specification. Whatever your requirements, we’re confident that our graphite machining services will serve your needs. We like a challenge, being a small firm fighting in a competitive market, we will machine that complex part everyone else turns down.